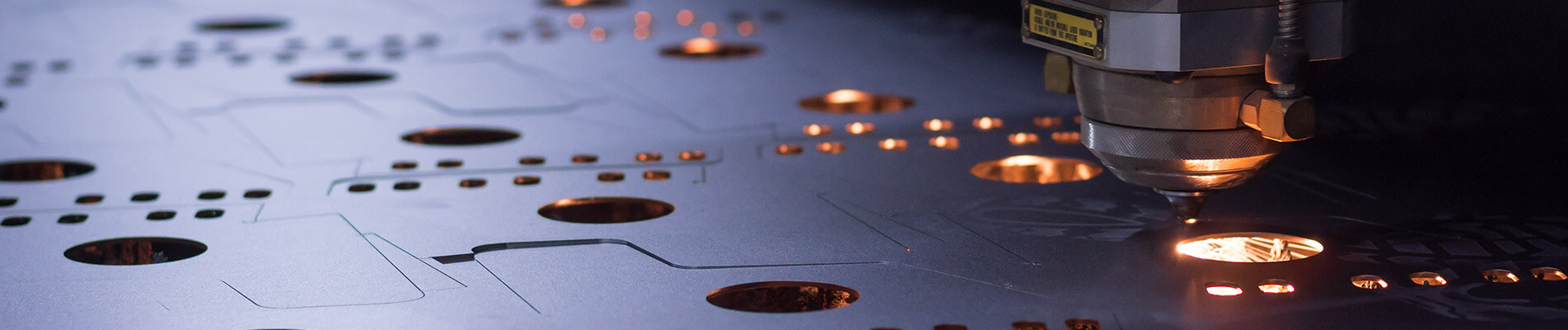

Laser cutting of sheet metal – fast metalworking with a high degree of detail

Laser cutting of sheet metal, tubes and profiles – our solutions, your benefits

Laser cutting of sheet metal, tubes and profiles – various types, sections and thicknesses

We use lasers to cut precise shapes from sheets with various thicknesses and properties. We cut stainless steel, copper, brass, aluminium, stainless steel and polished and ground steel.

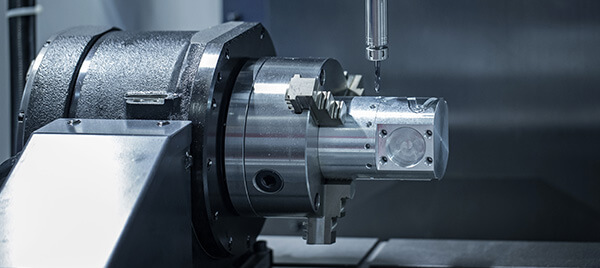

CNC hydraulic guillotine shears – faster implementation, no loss of material

Our machines are equipped with CNC hydraulic guillotine cutters maximum 3 m wide and 10 mm thick – the process is fast and with minimal material loss.

CNC-controlled machines – close to 100% repeatability of the most complex shapes

We use numerically controlled machines that allow us to cut complex, repeatable patterns regardless of the workpiece shape.

Laser metal cutting – check out our offer

We have state-of-the-art machines that support automatic, precise cutting of metal parts based on a prepared design. We process metal sheets, tubes and profiles with specific technical characteristics.

Sheet metal laser cutting

Working area – 3 x 1,5m

We cut out pieces with a maximum size of 3 x 1.5 m.

Laser power – maximum 6 KW

We use a 6 KW laser, which supports precise cutting with even edges.

Laser cutting characteristics

Black steel – maximum 24 mm

We cut black steel components from sheets maximum 24 mm thick.

Aluminium – maximum 12 mm

We cut aluminium sheets with a maximum thickness of 12 mm.

Stainless steel – maximum 14 mm

We cut stainless steel components with a maximum thickness of 14 mm.

Brass – maximum 10 mm

We have machines that allow us to cut brass sheets maximum 10 mm thick.

Laser cutting of tubes and profiles

Working area – 500 x 6000 mm/160 mm/10-160 mm

We cut tubes and profiles that are maximum 6000 mm long, maximum 160 mm wide and with diameters from 10 to 160 mm

Laser power – 2 KW

This type of laser allows efficient cutting of low to medium thickness parts.

Why to opt for laser sheet metal cutting?

Laser sheet metal cutting is a technique that gives you precise parts from which much more complex structures are made. At our facility, we take care of:

- compliance with the design – we use numerically controlled machines that operate in accordance with the uploaded design,

- without damaging the material – the laser beam hits a specific point, eliminating the risk of changes to the material structure and the need for further processing,

- edge quality – the techniques we use enable us to cut sheets efficiently while maintaining perfectly even edges,

- production rate – the techniques we use enable us to manufacture many repeatable items over a short time span.

We will manufacture components from steel, aluminium or copper sheets, which you will turn into finished metal products.

Order laser cutting in metal from MEBLOMET

Laser sheet metal cutting is a service aimed at both customers in need of quality intermediate products and those interested in the comprehensive manufacture of metal products. How do you use our services?

If you do not have a design ready, we will develop the design jointly with you. We will discuss all the details and select the right materials for the job.

Together we determine the order size, the deadline and the scope. We only carry out laser sheet metal cutting or the complete metalworking service.

We focus on efficient implementation. We comply with the deadlines agreed in the early phases of business relationship.

We handle the packaging and shipping of finished goods. We can offer to put the goods in ultimate boxes in which they will be shipped to the retail customers.

What elements do we cut out?

Laser sheet metal cutting is a technique used to manufacture a variety of products. Check out what products are made at our manufacturing facility and what we offer.

Medical accessory components

Sheet metal components for disabled equipment

City benches and garbage cans for the City of Mszana Dolna

Sheet metal cutting with laser – answers to FAQs

The exact price depends on a number of factors, such as the type of material, the thickness of the sheet metal, the complexity of the design and the number of items ordered. Please contact us for an accurate quote.

Laser cutting of sheet metal provides exceptional precision, with accuracy down to a few micrometres, allowing the creation of very complex and accurate designs.

We can cut a variety of materials and offer laser cutting of stainless steel, carbon steel, aluminium, copper, brass, as well as acid and polished and ground steel.

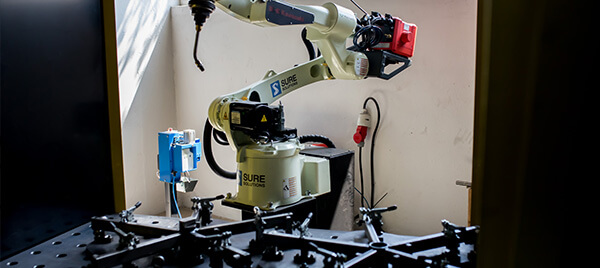

Other services offered by MEBLOMET

Grinding

We grind metal parts. We prepare parts of the structure for painting.

Welding

We are involved in the welding of metal components using MIG, MAG and TIG welding techniques.

Bending

We provide unique possibilities for bending metal parts in a very wide range of.

Choose to work with a partner who will take care of the manufacturing process for you. Let us know your expectations and we will prepare a quotation.