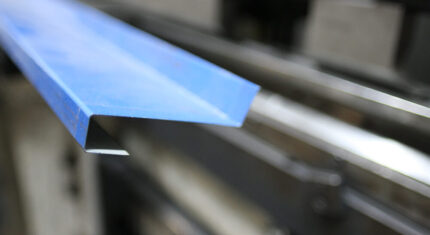

Bending of sheet metal and metal components over extremely wide ranges

Sheet metal, tube and profile bending – our solutions, your benefits

Completion of complex orders with 100% repeatability

Several decades of experience in bending and precision machinery, thanks to which we achieve 100% repeatability of often very complex bends.

Bending of steel tubes in various diameters

We bend steel tubes. We bend parts with diameters from Ø 12 mm to Ø 114.3 x 5 mm.

Bending of steel profiles

We have machines that allow us to bend steel profiles maximum 40×40 mm. We use mandrel and mandrel-free bending machines.

What elements do we bend?

The technologies we use allow us to bend sheet metal, tubes and steel profiles. Check out the components we process at our production facility.

Bending parameters

Bending parameters

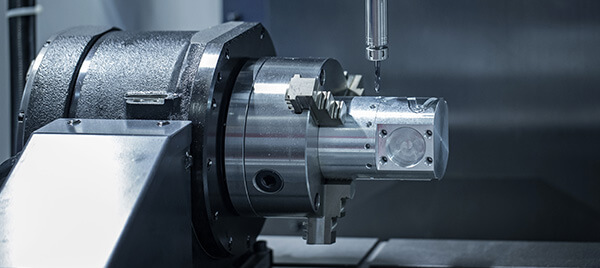

Our CNC-controlled press brake enables us to bend metal sheets quickly and very precisely.

Maximum sheet width: 300 mm

Maximum thickness: 6 mm

We also bend shorter pieces maximum 8 mm thick.

Tube bending

We bend steel and aluminium round tubes.

Tube bending range: maximum Ø114,3

Maximum wall thickness: 5 mm

Profile bending

We have mandrel and mandrel-free bending machines. These are used for precision bending of steel and aluminium profiles.

Bending of steel profiles: maximum 40×40 mm, max. wall thickness: 2 mm.

Aluminium profile bending: maximum 40×40, max. wall thickness: 3 mm.

Why bet on sheet metal bending at MEBLOMET?

We approach each order individually, with complete professionalism. When using our sheet metal bending services, you can count on:

- bending in very wide ranges – we use drive systems that allow bending in various ranges,

- 100% reproducibility – even with very complex bends,

- our complete control of the process – permanent deformation without compromising material integrity,

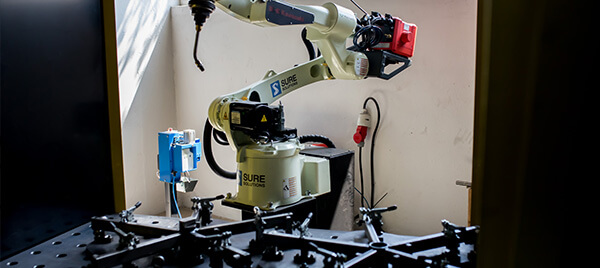

- state-of-the-art machinery base and manufacturing facilities – capable of bending small parts and large structures in single orders and high volume production.

We deal with the bending of steel and aluminium sheets. We provide professionalism and an individual approach to each project.

How to use the bending services at MEBLOMET?

Sheet bending is a service aimed both at customers in need of quality semi-finished goods and those interested in the complex fabrication of metal products. How do I order bent sheet according to your design?

All you need to do is provide us with the documentation. If you do not have a ready-made design, we will prepare it together.

Together we determine the order size, the type of material, the bending method, the completion date and the scope. We perform sheet bending alone or combine this service with others.

We focus on efficient implementation. We meet the deadlines agreed in the early phases of business relationship.

We take care of the packaging and shipping of the finished goods. We also use bent sheets to manufacture the components necessary for more complex projects.

What products do we produce as part of our bending service?

Using sheet metal bending, tube bending or profile bending, a variety of even the most complex products are created. Check out the products we manufacture at our facility.

Chair frame bending

Bending tubes and profiles for fitness gyms

Bending parts on a press brake

Sheet metal bending, tube bending, profile bending – answers to FAQs.

Yes, our advanced CNC machines allow us to bend sheet metal, profiles and tubes in unusual shapes and complex designs. Please send us detailed specifications to assess the feasibility of your project.

In order to prepare a quote, we need detailed information about the project, including technical drawings, material specifications, dimensions and data on the number of elements.

Our equipment allows us to bend sheets maximum 3.1 m in length and maximum 6-8 mm in thickness. Detailed information on our technical capabilities can be obtained by contacting us directly.

Yes, we are able to carry out small, one-off orders as well as large, series productions.

Yes, we offer additional services such as cutting (preceding bending) and subsequent welding, shot-blasting or powder coating powder coating, to provide a comprehensive service for projects. We pack and ship the finished goods.

Other services of MEBLOMET

Grinding

We grind metal parts. We prepare parts of the structure for painting.

Welding

We are involved in the welding of metal components using MIG, MAG and TIG welding techniques.

Sheet metal laser cutting

We offer laser cutting of sheet metal with maximum dimensions of 3 x 1.5 m.

Choose to work with a partner who will take care of the manufacturing process for you. Let us know your expectations and we will prepare a quotation.