Metal surface grinding service with quality assurance

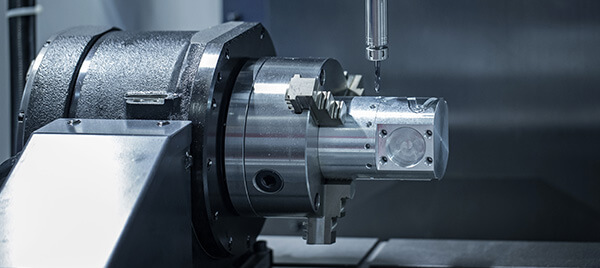

Metal grinding with the advanced eccentric grinder

Metal precision grinding

For metal grinding, we use advanced machines that guarantee full compliance with the design and high surface quality of the finished goods.

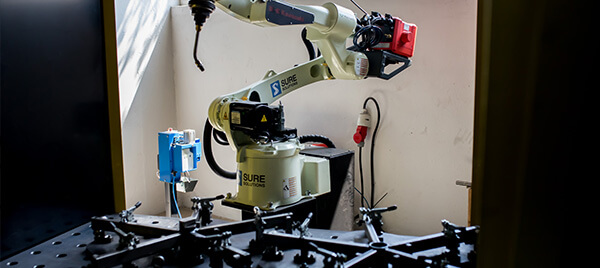

Piece or series production

Our machinery base enables us to manufacture both single prototypes and large lot orders, tailored to the customer’s needs.

Quality control of ground components

Each product is subjected to rigorous quality control and our customers receive full documentation confirming the tests carried out and standards met.

Why to opt for metal grinding services at MEBLOMET?

We carry out grinding of individual products and entire series of repeatable products. We use machines adapted for machining flat surfaces of various materials – black steel, stainless steel and aluminium.

- Fast turnaround – modern machinery base and a skilled team enable us to execute orders with tight deadlines.

- Comprehensive service – in addition to grinding, we offer a wide range of additional services such as milling, bending, welding or shot-blasting.

- Personalised approach – we offer flexibility in the execution of orders, adapting to the customer’s needs and requirements.

- Quality control – every step of the process is monitored and our products undergo thorough quality control. The customer has access to the documentation of the quality tests.

Professional, industrial grinding of metal surfaces

How can I place order for a metal grinding service from MEBLOMET?

We grind products that are made primarily for business customers. We grind products supplied to us and those developed from scratch at our plant. How do you work with Meblomet?

To begin with, it is necessary to provide us with the documentation that will be followed during execution of metal grinding process. If you do not have a complete design, we will develop it jointly with you.

Together, we determine the order size, the completion date and the scope of the commissioned job.

We focus on efficient implementation. We meet the deadlines agreed in the planning phase of business relationship. We also provide expert technical support and advice.

We take care of the packaging and shipping of the finished goods. If grinding is the final processing step, we can place the product in the ultimate packaging.

Grinding – our project highlights

Grinding is used to manufacture a variety of metal products. Find out what products we machine most commonly at our manufacturing facility and what we can offer you.

Grinding of chair frames

Grinding and powder coating of fitness equipment

Grinding and powder coating of gym equipment

Grinding metal – answers to FAQs

In our Company, we grind black, stainless steel and aluminium planes. We have suitable machinery base for processing both hard and soft materials. You can order the following services from us:

- grinding of black steel

- grinding of stainless steel

- aluminium grinding

We carry out both piece and series production orders. Thanks to our machinery base, we can cater for various customer needs.

The duration of the grinding process depends on the project complexity, the type of material and the number of components. After analysing order details, we provide an indicative completion date.

Yes, we offer technical consultation in every phase in every project phase. Our experts can advise on the selection of grinding techniques and process characteristics.

Other services offered by MEBLOMET

Welding

We are involved in the welding of metal components using MIG, MAG and TIG welding techniques.

Bending

We provide unique possibilities for bending metal parts in a very wide range of.

Sheet metal laser cutting

We offer laser cutting of sheet metal with maximum dimensions of 3 x 1.5 m.

Choose to work with a partner who will take care of the manufacturing process for you. Let us learn about your expectations and we will develop a quote for you.