MEBLOMET welding services – durable and eye-catching joining

Professional metal welding – our solutions, your benefits

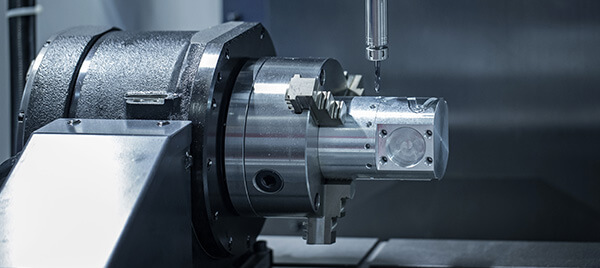

MIG, MAG, TIG welding techniques – precise, robust joining of components

We deal with welding using all proven techniques – MIG, MAG and TIG – applying welding robots and semi-automatic machines.

Serial welding with rapid time and full repeatability

We weld metal components in series ranging from a few to tens of thousands of pieces – in rapid time and with 100% repeatability.

Precision welding of metal parts regardless of size

Thanks to the precision robots and the experience of the personnel , we are able to weld both large-volume components and those just a few metres long.

Why rely on our welding services?

We rely on professional welding services carried out by experts with many years of experience. We use machines that enable us to carry out large-size production.

- Among other things, we carry out MIG welding of large-size components, maximum several metres in total length.

- We guarantee the durability and aesthetics of the joints we make – we conduct tests to control their quality.

- We use all basic techniques, which include MIG, MAG and TIG welding. This allows us to join parts made of different metals.

- We offer comprehensive metalworking services – in addition to welding, we can also provide a range of other services, preparing a product from scratch.

Rely on our experience and proven manufacturing process to develop quality metal products for your customers.

How to start business with MEBLOMET?

We provide welding services according to the customer’s design. We carry out individual and wholesale orders for companies in various industries. How to do business with our Company?

All you need to do is provide us with documentation of the structure to be welded together. If you do not have a design ready, we will prepare it together.

Together we determine the order size, the welding method, the type of material and the deadline. We can carry out welding only or a package of metalworking services.

We focus on efficient implementation. We meet the deadlines agreed in the early phases of business relationship and keep you posted about work progress.

We take care of packaging and shipping of the finished goods. We can also prepare welded structures for sale to retail customers.

MEBLOMET welding services – gallery of selected projects

Welding is a tried-and-tested and effective method of creating permanent connections that allows even the most complex metal structures to be created. See the products we manufacture most often.

Welding components of outdoor gym equipment

Welding of sports arena fence panels

Welding of medical chair components

Welding metals – answers to FAQs

Our Company specialises in welding carbon steel, stainless steel and aluminium as well as copper and its alloys. We have the appropriate tools and experience to ensure the top quality welds. We offer:

- MIG welding of aluminium

- TIG welding of aluminium

- MIG/TIG stainless steel welding

- TIG welding of black steel

To obtain a quote, please send us detailed information about your design such as technical drawings, specifications and number of components. Our team will prepare a custom quote based on the data inputs.

Lead times depend on the design complexity and the size of input. Usually, however – due to the process automation and the large capacity – we are able to offer a short lead time. Once we have details of your requirements, we can provide you with an estimated production completion date.

Each design is inspected by our experienced staff. We carry out regular tests to ensure that the finished goods meet top quality standards.

Yes, we offer technical advice in every project phase. Our professionals can help you choose the right welding techniques, materials and parameters.

Other services

Grinding

We grind metal parts. We prepare parts of the structure for painting.

Bending

We provide unique possibilities for bending metal parts in a very wide range of.

Sheet metal laser cutting

We offer laser cutting of sheet metal with maximum dimensions of 3 x 1.5 m.

Choose to work with a partner who will take care of the manufacturing process for you. Let us know your expectations and we will prepare a quotation.